Linn makes sound investment in quality with Mitutoyo

Globally renowned as a leading designer and manufacturer of high-fidelity sound systems, such as turntables, streaming systems, amps and speakers, Linn Products employs approximately 160 people at the company’s impressive Glasgow based HQ. Rather than pursue a business model of planned obsolescence, due to the modular nature of Linn Products’ hardware and software, all of the company’s systems are upgradeable. In addition to their ability to evolve, the enduring quality and longevity of the company’s systems, ensures the best sound possible for the lifetime of each product.

Quality permeates every aspect of the business’ activities. To ensure the build-quality of Linn Products’ celebrated products and to guarantee their outstanding sound reproduction and clarity, in addition to long lasting performance, the company’s staff perform painstaking inspection routines throughout all stages of manufacture.

To reduce the company reliance on subcontractors, further increase the autonomous nature of the business’ impressive manufacturing operation and to provide even greater control over the quality of its components, Linn Products recently made several major investments in advanced machine tools.

To reduce the company reliance on subcontractors, further increase the autonomous nature of the business’ impressive manufacturing operation and to provide even greater control over the quality of its components, Linn Products recently made several major investments in advanced machine tools.

These investments included the purchase of a bespoke manufacturing cell from Mills CNC. The fully automated system includes a Doosan DVF 5000 5-axis machine tool and a Fanuc industrial 6-axis robot. The impressive new cell now runs unattended overnight and over weekends and has provided significant productivity gains.

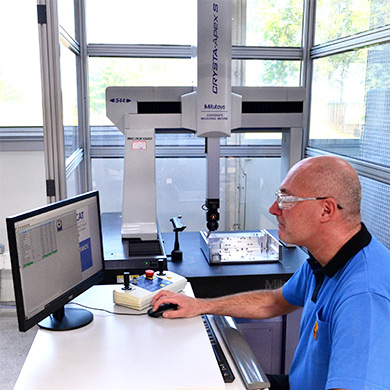

Due to the enhanced accuracy capabilities and the high-yield nature of Linn Products’ new manufacturing plant, Chris O’Brien, Linn’s Director of Operations searched for an advanced Coordinate Measuring Machine (CMM) that had the ability to keep pace with the company’s increased production of precise components. Following a successful, practical demonstration at Mitutoyo’s East Kilbride showroom, an order was placed for a recently launched CRYSTA-Apex S Series CNC CMM.

Explaining Linn Products passionate quality philosophy and the purchase of the CRYSTA-Apex S Series CMM, Chris O’Brien said. “Ever since Linn Products was established in 1973, we have constantly pushed technology forwards in the pursuit of perfect sound. From our very first product, the iconic Sondek LP12 turntable, we have been at the forefront of audio technology.

“All of our high-fidelity sound systems are assembled by hand in our Glasgow factory, and each one bears the name of the person who made it. Our systems are engineered to extraordinarily tight tolerances. To help ensure the continuing premium quality of our products and to guarantee their prolonged superior performance, all systems are painstakingly inspected and tested at each stage of manufacture. Then, prior to despatch, every product is thoroughly tested to ensure that they deliver outstanding performance.

After bringing machining of many of our previously sub-contracted, high-precision components ‘in-house’, we needed to source a highly efficient and very accurate means of inspecting them. Having considered other options, a demonstration of a CRYSTA-Apex S Series machine at our local Mitutoyo showroom proved that it was the ideal advanced CMM for our demanding needs. As it had the ideal to size to accommodate our components, we ordered a Crysta-Apex S544 model with an x,y,z, capacity 500 mm x 400 mm x 400 mm.

“Following our new Mitutoyo CMM’s trouble free installation our Engineering staff were trained in its operation. As the CMM’s operating system and software are so logical and intuitive our staff soon became able to perform a range of inspection routines. Although, when needed they are able to receive help over the telephone from Mitutoyo’s technical staff. Our CRYSTA-Apex S Series machine is now making a significant contribution to Linn Products quality management systems.”

Mitutoyo CMMs are available in a wide range of sizes and accuracy classes enabling them to cover practically all precision 3D measuring applications. A large variety of contact and non-contact probes are offered, enabling a wide range of different measurement routines to be performed. Complementing Mitutoyo’s celebrated CMM hardware, the company’s powerful, yet easy to use analysis software allows all measurement results to be interpreted in the timely manner so essential for keeping pace with today’s fast-paced production speeds.

Mitutoyo CMMs are available in a wide range of sizes and accuracy classes enabling them to cover practically all precision 3D measuring applications. A large variety of contact and non-contact probes are offered, enabling a wide range of different measurement routines to be performed. Complementing Mitutoyo’s celebrated CMM hardware, the company’s powerful, yet easy to use analysis software allows all measurement results to be interpreted in the timely manner so essential for keeping pace with today’s fast-paced production speeds.

The CRYSTA-Apex S series are high-accuracy CNC CMMs that guarantees a maximum permissible length measurement error of E0,MPE=(1.7+3L/1000) μm [500/700/900 Series]. In addition, the advanced CMMs deliver a maximum drive speed of 519 mm/s and a maximum acceleration of 2,309 mm/s2, resulting in an increase of almost 100 mm in drive distance in one second, when compared with general-purpose CNC CMMs.

Designed to deliver high rigidity, Mitutoyo’s Crysta-Apex S series CMMs feature unyielding structures. Their Y-axis guide rails, which is attached to one side of the machines’ granite surface plates, helps the machines to maintain high levels of accuracy over years of use. The CMMs’ air bearings are located on their guide rails’ bottom faces, also on the front, rear, and upper surfaces of the slider unit of the X-axis. This arrangement helps to minimize vibration even during high-speed, high-acceleration movements and ensures stable linear motion. The high speed and high acceleration qualities of CRYSTA-Apex S CMMs dramatically reduces measuring times.

In addition to being an ideal CMM for use in pristine quality departments, thanks to the use of a temperature compensation system CRYSTA-Apex S CMMs are able to guarantee the accuracy of measurement under temperature conditions of 16 to 26 °C. Mitutoyo’s ingenious system, is based on permanently installed temperature sensors located on each scale working together with sensors placed on the workpiece.